Une architecture stimulante

The gleaming office building of Farming Agrícola literally rises out of the earth among the cereal fields. © Farming Agrícola

Thanks to the green roof areas that reach right down to the ground, the architecture blends perfectly into its surroundings.

Floor to ceiling glass facades on the gable ends of the building allow for easy glimpsing into and out of the building, lending it even more charm.

A step is incorporated into the pitched roof of the two-storey main building allowing for the creation of a balcony with a glass balustrade.

The balcony is open to all to take a break al fresco with a panoramic view.

You will also have a wonderful view if you take this stairway up to the roof of the single storey building. The beautiful roof terrace also has a glass balustrade.

It actually looks as if the colourful meadow flowers are climbing to the roof to make it even more beautiful. © Farming Agrícola

The vegetation mats, Mediterranean Flowering Meadow, suited to the local climate, gradually reveal their sophisticated floral splendour.

The roof is transformed into a sea of colour by 20 or more different species.

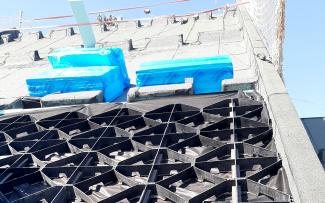

The steep pitched roofs were fitted with stable, flashed shear barriers, XPS thermal insulation (inverted roof) followed by the ZinCo system build-up with Georaster® elements.

The interlocking Georaster® elements were installed with precision and are capable of absorbing shear forces of up to 800 kg/linear metre.

The correct base is vital: Shear transfer and protection against erosion are the most important aspects to be considered when installing a green roof on steep pitched roofs.

Thanks to the low volume of the Georaster® elements, a lot of space is available for rooting in the substrate area – and solid rooting is the best protection against erosion.

The system substrate Roof Garden is held firmly in place in the 10 cm high Georaster® elements.

The 40-45° pitched steep roof areas are very well prepared with the system build-up Steep Pitched Green Roof with Georaster® elements.

The roofs with a 20° pitch were fitted with the system build-up Pitched Green Roof with Floraset® FS 75 and the flat roofs were fitted with Floradrain® FD 25 (foreground).

Green roof on office building in Villamartín de Campos, Spain

The modern company headquarters of the family business, Farming Agrícola, which is involved in the agricultural sector, is proof of its innovative strength in all respects. Located on a 32 Ha site, with approx. 1,000 m² of planted roof area, this unique building is eye-catching from every side. The extraordinary structure gives the impression that it is rising gently out of the ground. This is due both to the roof areas that reach right down to the ground and the light and graceful elegance of the glass facades. For this reason, the green roofs are very interesting from a construction point of view given that three different ZinCo system build-ups were required for the different roof pitches of 4°, 20° and 40–45°. Firmly held in place and stable, the Mediterranean Flowering Meadow is adapted to suit the hot arid climate of the region and will thrive there.

The company history of Farming Agrícola begins in the 1980s when Luis Delgado, father of today’s owner, Juan Carlos Delgado, followed his dream and began to import and deal in German agricultural machinery from Krone and Amazone. Further top brands were to follow over the decades, resulting in Farming Agrícola now being one of the most modern companies in the agricultural sector in Spain and Portugal. The new company headquarters is 17 km from Palencia, in the heart of the northern Spanish region of Tierra de Campos (Engl.: Land of fields), in the autonomous community of Castile and León. Tierra de Campos was and continues to be the breadbasket of Spain and is characterised by a virtually flat and rain-free land mass. The logistics, technical and sales departments along with a demonstration space and a new training centre are located on the 32 Ha company site. Rising up between the large warehouses and the cereal fields, the unique office building houses administration and management.

One of the key objectives of Farming Agrícola is the training of their own staff, dealers and also farmers and students.

“We have a staff of 110, of whom 60 are based at the new company headquarters and 50 at our branches. People are our most important asset”, says Juan Carlos Delgado, who has created a unique ambiance for staff and visitors alike with this new and innovative green roofed building.

Architectural jewel

Architecturally speaking, the two-storey office building can in principle be classified as an A-frame structure, given that the roof areas reach down to the ground, and it has a vertical wall only on each of the gable ends. In addition, the elongated structure is divided into two sections. There is a smaller, single storey building at the side of the main building, that hugs the larger building. A long stairway leads from the ground directly to the roof of this building, to a wonderful terrace. A very nice balcony has been integrated into the roof of the main building by creating a step in the sloping roof. This open area is accessible from the upper floor.

In keeping with the floor to ceiling glass facades of the entire building, glass balustrades are used for the balcony and the roof terrace. Not only has glass the effect of being light and airy, but more importantly it lets the daylight into the rooms and creates a close connection between indoors and outdoors. The windows allow for a wonderful panorama view and good ventilation.

The most significant link with the surrounding landscape is, naturally, the green roof itself. It has a temperature-balancing effect – providing thermal insulation in the winter and cooling in the summer – and therefore extends the service life of the roof waterproof membrane. It also filters dust and pollutants and enhances the sound insulation. The value added to architecture with this green roof is truly priceless.

Up to the steepest spot

Basically, provided it is professionally planned and executed, installing a green roof on roofs with a pitch of up to 35° is always possible. However, if a roof has a greater pitch, the feasibility of a green roof on the property in question has to be specifically examined and more complex measures will be required in relation to the transfer of shear forces and protection against erosion.

The roofs of the office building can be divided into three different types: first is the 540 m² area with a 4° pitch (flat roof). Beside that is an area of 50 m² with a 20° pitch (pitched roof), and areas with a combined 420 m² with a 40–45° pitch (steep pitched roof), which presents the greatest technical challenge when installing a green roof.

The top priority with pitched roof areas is to transfer the extremely high shear forces into the roof structure via stable abutments. For this purpose, the roof edges were designed to be high and stable, and apart from that, additional shear barriers were anchored within the roof areas. Based on structural calculations, the height (approx. 30 cm) and distance between the shear barriers (approx. 2.50 or 4.35 m) are designed precisely to suit the shear forces. In order to ensure the run-off of excess water from the roof areas, the shear barriers are interrupted at regular intervals across the entire roof width (approx. 9 m).

The first layer to be installed on this sturdy roof structure including all shear barriers was a root-resistant bituminous waterproof membrane followed by the thermal insulation layer made of XPS hard foam. This inverted roof build-up requires permeable layers on top, which is why the first layer in the green roof build-up is the vapour permeable Separation Membrane TGV 21.

Robust in all respects

In order to ensure it is secure, not only is the described sub-structure with shear barriers of relevance, but also the chosen green roof build-up in the surface. In this case, the choice clearly came down on the side of the ZinCo system build-up Steep Pitched Green Roof with Georaster® elements. These 54 x 54 cm interlocking grid elements made from recycled plastic immediately create a stable, extensive bond that can absorb shear forces of up to approx. 800 kg/linear metre and prevent the substrate layer from slipping. Thanks to the low volume of the elements, the space remaining for rooting is relatively large. This is an important factor as the quicker the subsequent plants can take root, the lower the risk of erosion.

The installation work started at the lower end of the roof and continued upwards, row by row, carefully fitting the elements within the limitations created by the roof edges along the side and the shear barriers. As the Georaster® elements are exactly 10 cm high and are filled with substrate, this is the precise substrate depth that is available. The system substrate Roof Garden was delivered in big bags, lifted onto the roof by crane and distributed manually across the entire area. Once the dripline irrigation system was installed, everything was ready to go for the future magnificent plant coverage.

Tailor-made solutions

Given that this multi-facetted building also has flatter surfaces, additional ZinCo system build-ups made a splendid appearance.

The system Pitched Green Roof with Floraset® FS 75 was suitable for the roof area with a 20° pitch (50 m²). In this case, the substrate interlocks very well with the large troughs in these approx. 75 mm high drainage elements made of EPS hard foam. The extensive bonding of the elements absorbs shear forces and transfers them to the roof structure.

For the flat roof with a 4° pitch (420 m²), the ZinCo system build-up with Floradrain® FD 25 was the perfect choice. The 25 mm high drainage elements made of recycling plastic are used for storing water in the troughs on their upper side. The reason for this is that water can of course collect in the elements on the flat roof, be it stormwater or from the dripline irrigation system. After covering the Floradrain® FD 25-E with the System Filter SF, 10 cm of system substrate Roof Garden was added, as with the pitched roofs, so that the ground was evenly prepared for the vegetation.

Pre-cultivated in Spain

Complete vegetation coverage is the most important element of protection from erosion, which is why, in principle, only pre-cultivated vegetation mats and not planting itself are the only option for the initial growth phase on steep pitched roofs with a pitch of 30° or over. When establishing growth, it is also important that the types of plants used are suitable for the local climate. With this green roof, the conditions are actually ideal as the vegetation mats were cultivated in Spain.

The type used here, Mediterranean Flowering Meadow, is simply meant for the arid climate of Southern Europe with its high level of solar radiation.

The three sedum types and two grass types create a common base for more than 20 species of robust, blossoming perennials such as the Carthusian Pink (Dianthus carthusianorum), the Viper’s Bugloss (Echium vulgar) or the Sea Thrift (Armeria maritima).

The installed irrigation system provides for the quick establishment of the vegetation mats and for the water required by the Mediterranean Flowering Meadow, which incidentally has to be mown now and again. This richly blooming symphony lends its very own special charm to the architecturally impressive building and is in perfect harmony with the surrounding landscape – a truly uplifting and radiant green roof project.

Author: Fabian Kaiser, Head of International Sales, ZinCo GmbH

Site board

Construction project: Office building of Farming Agrícola, C/ Paraje La Gata S/N, 34170 Villamartín de Campos (Palencia), Spain

Client: Farming Agrícola, 34170 Villamartín de Campos (Palencia), Spain

Construction year: 2021

Roof area: approx. 1,010 m²

Green roof build-up: ZinCo system build-ups depending on the roof pitch with Floradrain®, Floraset® and Georaster®

Architects: MODOS ARQUITECTURA, 34004 Palencia, Spain

Execution: Jardinería Diego S.L., 39478 Puente Arce, Cantabria, Spain

System supplier: ZinCo Cubiertas Ecológicas S.L., 28001 Madrid, Spain

System manufacturer: ZinCo GmbH, 72622 Nuertingen, Germany